|

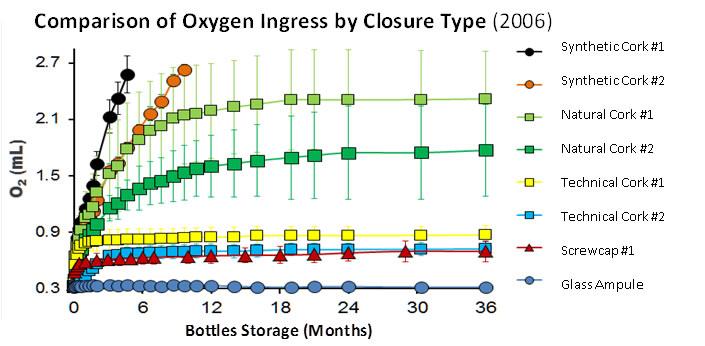

There are noumerous enclosures to choose from made from different materials. The traditional natural cork is the best known, and is made from Cork typically produced from the bark of cork trees grown in Portugal. Natural cork is made by punching the cork from a sheet of cork bark. There is also a couple of cork derivatives, developed for cheaper, and in some applications enhanced performance: Agglomerated cork and Colmated cork. Agglomerated cork enclosures are made from granulated cork, which typically is a by-product from the cork production. The granulated cork is rinsed.for impurities including TCA, prior to being molded - by 'glue" - into a bottle cork shape. This type of cork is typically not recommended for longer life wines. The time in bottle should be less than 18-24 month. We have had good success with this type of enclosure in white wine. Oxygen ingress is in the same order as screw top closure, largely keeping oxygen out of the bottle. Colmated Cork enclosures are another type of low cost cork enclosures. This type is most often a combination of a lower grade natural cork combined with finely granulated cork to fill in cracks and cavities in the natural cork. Like the agglomerated cork, the granulated cork is held together by glue. Life-span of this type of cork enclosure is specified to be in the same range as the agglomerated cork of up to a couple of years. We have had less success with this type of enclosure. In one case the glue failed and partially dissolved the cork tip, The photo above shows an agglomerated cork, after 5 years in a bottle. The wine was well kept in the bottle. The cork shows some signs of change in structure, but this change did not affect the wine. Looking at alternatives to cork enclosures we have : Synthetic cork, glass corks and screw tops. Synthetic corks are attractive as they appear and behave very much like natural corks. That means that you will not need to reconfigure a bottling line, both natural and synthetic cork can run on the same line. Oxygen ingress appears to be the highest of any of the enclosures. The extra oxygen in the wine over time can potentially change the character of the wine faster than desirable. In an earlier post I have a section about synthetic cork. A sliced synthetic cork. The inside is a foam like substance, while the exterior is a "skin-like" material.

Glass corks were popular a few years back. They are shaped like a traditional bar top cork. I do not have real experience with this type, other than from opening a few bottles with glass corks. A convenient feature of glass corks is that no corkscrew is required to open the bottle, while the bottle in unopened condition will appear similar to a natural cork bottle. As with screw tops this type requires a different line configuration than the natural and synthetic cork types. Oxygen ingress is very low, some measurements show a close-to-zero oxygen ingress. If I were to suggest a use for this, I could think of certain types of white and rose wines. Screw tops are becoming more and more accepted for wine. It is an ideal type of enclosure for wine by the glass etc. The bottles are very easy to open. The cost of screw tops is lower than natural cork. Oxygen ingress is low, which means that wines sensitive to oxygen will benefit from this type. As with glass corks this requires a difference bottling line configuration. I would not hesitate to use screw tops for white and rose wines, as I think the wine will keep better compared with natural cork.

0 Comments

Corks are not corks … the corks are there mainly to control the long term oxygenation of the wine, allowing the wine to age but not to spoil untimely. We need to consider how long time the wine is warehoused and stored as part of the selection, in other words: how old will the wine be at the time it is consumed. Some wines are intended to be consumed as soon as possible, and others may become collectors items. There are many different parameters we need to select. Parameters such as :

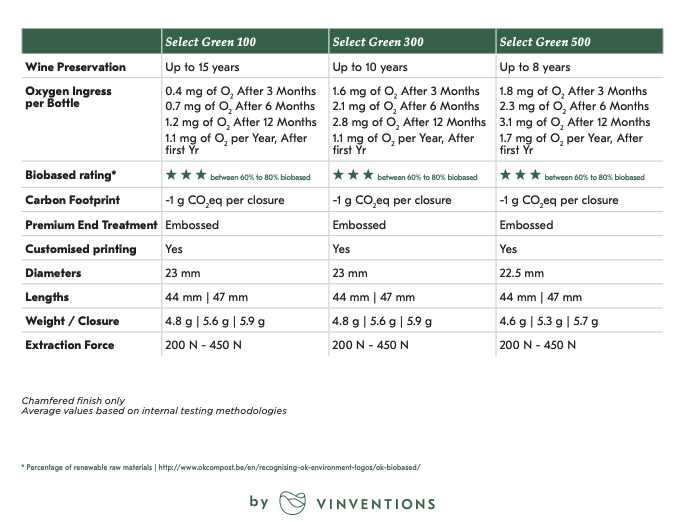

Recently we experienced significant problems with oxygen in our wines. We started to research the reasons, and believe that it could be related to lack of fit to bottle neck as well as surface treatment of the cork itself. To ensure proper quality of our bottling process we will need to have a specification for each of the cork parameters. Our cork specification shall be used with every purchase of cork material. Furthermore we need to ensure the we have a good overall fit to the bottles neck. We can do that by doing a small bottling run, e.g. using water. Note to self: The curves and table below have different units, so before comparing make sure to have the right conversion. For now I assume 1 ml O2 is equivalent to 1.429 mg. Lopes, P.; Saucier, C.; Teissedre, P.L.; Glories, Y. Impact of storage position on oxygen ingress through different closures into wine bottles. J. Agric. Food Chem. 2006. 54.6741-6746

There are several reason's why cork fail as enclosures for wine bottles. The most common is due to TCA which taints the wines with odor and aroma resembling wet cardboard. TCA is a compound created during the processing of cork it self (bleaching) or it can be created on the cork tree itself as a result of e.g. a chemical reaction with herbicides or pesticides.

We have experienced a fair amount of problems with TCA, in severe cases with as many as 1-2 bottles per case which is about 10 times more than typical occurrence. TCA is not visible on the cork itself, but can easily be smelled on the cork or in the wine glass. Most wineries are constantly looking for enclosures that behave like traditional cork but without the TCA contamination risk. The other problem is leaking corks as seen in the photos above. Leaking by itself is not necessarily a problem, but it opens up for problems as leaks create a transmission channel for unintended transmission of e.g. oxygen or worse transmission of bacteria etc. Finding the perfect cork / enclosure is a tradeoff of oxygen ingress, potential odor contamination (besides TCA in natural corks it can be a problem with synthetic corks due to the material) and the potential for leaks. In many cases the result will not be visible until the wine is aged well. That makes the choice of corks / enclosures a really important task. Synthetic corks are attractive to use as one would expect less failures compared with real cork, due to inconstancies in real corks and due to potential TCA issues. As it turns out some of the synthetic corks I have tested give off undesirable odor. I first noticed something off with the aroma of a wine, and noticed that the synthetic cork had the same "aroma". I opened other types of wines with the same synthetic cork product and found the same odor. I can best describe the odor as "burnt rubber". These corks had been in bottle for 1-5 years but all exhibited the same odor issue. I do not want to divulge the wine or the cork, as my point with this post is to point out a real potential issue with synthetic corks.

Another issue that synthetic corks may have, is the higher amount of oxygen ingress, potentially aging the bottle content faster than a real cork. At this point I recommend that a small bottling trial is used for determining the suitability of a synthetic cork. Other considerations would be around life span of the wine, whether the wine is expected to sell immediately, or to be kept for aging. Topping, racking and refilling process and procedures (For Wine in Barrel)

As part of our premium quality goal we are changing our processes for handling wine. The following is a list of processes and procedures that we will follow, although details such as air draining, oxygenation etc may not be included in these description (if you are looking for this information please contact me for details). Topping Topping is the process of keeping oxygenated air out of the wine barrels by continuously keeping the barrels filled to the brim. Wine evaporates or is removed for testing and tasting, so we need to watch the wine levels in the barrels and refill regularly. As part of our process for premium wine, topping wine has to be primarily the exact same batch of wine, so fx a pinot noir estate, vintage, block, press etc has to be identical between the topping wine and the content of the barrel to be topped. To make that work, we will use variable size tanks for the topping wine, in order to keep oxygenated air out of the topping wine. For now we will be using stainless steel tanks for the topping wine. alternative methods of filling a bag inside the barrel with liquid could be considered. If for some reason we do not have the correct / desired topping wine as described above, the topping wine has to be selected by a committee of our sommelier, winemaker and owner. As part of the process, the wine is FOSS tested as well as tasted by our sommelier for quality control purposes. The results will be filed on our shared wine folder. Racking Our red wines are currently not filtered prior to bottling / keg-ing. The racking process combined with the barrel aging will be used as the primary method for separating wine from lees, by clarifying the wines over time. Our goal is to continue to avoid filtration in our wine process. Filtration of small amounts of wine may be needed and accepted in order to avoid waste. Wine of the exact same kind may only be racked together. Pinot Noir Estate free run, may not be mixed with Pinot Noir Estate pressed as an example. Refilling The refilling will go into cleaned barrels of the same kind of wine. Final Racking. The end-goal is to be able to blend a reserve wine version from our absolute best tasting, cleanest and best looking wine, that will be bottled unfiltered, clear with great color. For now this means that in the final racking process the reserve wine must only consist of the top part of the barrel, so as an example only the first half of the barrel will be racked as the reserve wine, and the second half with potentially more lees will be used for estate. Immediately after a barrel is racked it must be closed in order to protect the wine from oxygenation. The reserve wine will be racked first. After the final racking for reserve labelled wine is completed and the blend as has been tasted and approved for bottling, the regular estate will be racked and assembled. Final estate version racking will follow immediately after the completed reserve racking. Estate racking can consist of two steps. First the remaining barrels are racked so they are almost completely empty, leaving wine with high content of lees in the barrels. This process is immediately followed by adding filtration of the very last barrel content in order avoid waste. The need for filtration will be determined at the time of final racking, by measuring the clarity of the wine. |

Benny MadsenLos Altos Vineyards, Byington Winery and Tin Cross Vineyards ArchivesCategories |

Proudly powered by Weebly

RSS Feed

RSS Feed